IMPORTANCE OF ESD STANDARDS IN PCB ASSEMBLY

- TapRen Team

- 3 days ago

- 10 min read

Abstract

Electrostatic Discharge (ESD) might not be visible, but its effect on PCB assembly is nothing short of immense. Electronic devices are highly sensitive to uncontrolled sparks, which can permanently damage the product, resulting in significant losses and potentially necessitating a product recall. Hence, the adoption of ESD standards is not only a best practice but also a necessary one in contemporary electronics manufacturing. Whether it's consumer devices or industrial equipment, an ESD-safe working environment leads to long-term reliability, performance, and compliance. This article will discuss the importance of ESD standards in PCB assembly, the key guidelines to follow, and some proven methods to ensure that your circuit boards are not silently and fatally damaged by ESD.

UNDERSTANDING ESD IN ELECTRONICS

Electrostatic Discharge (ESD) refers to an unexpected movement of electricity between two electrically charged bodies. It typically occurs when electrically charged objects of varying electric potential come into contact (e.g., a human hand touching a circuit board). The PCB may break or damage sensitive semiconductor components, even with a discharge as low as 30 volts, which is well below the level that a human can sense.

During electronics manufacturing, ESD may occur at various stages, including soldering, packaging, and inspection. The usual sources are workers, tools, and improperly grounded surfaces. They can cause sudden discharges into the components when these elements contain static electricity, resulting in immediate failure or latent, long-term defects.

In PCB assembly, the risk of ESD is particularly acute, as integrated circuits and microchips are very sensitive. Poor ESD control measures mean manufacturers will have decreased product life cycles, increased returns, and even safety concerns. Learning about the mechanism of ESD is the initial step towards creating a safe, reliable, and ESD-compliant manufacturing environment.

IMPORTANCE OF ESD STANDARDS IN PCB MANUFACTURING

Electrostatic Discharge (ESD) standards are crucial for ensuring the safety of delicate electronic components in PCB production. These are industry-recognized specifications that help limit product failures, ensure quality control, and maintain reliability between production runs. By adhering to ESD standards, manufacturers can prevent costly damage, ensure global compliance, and enhance customer satisfaction.

Safe Guard Sensitive Parts

The ESD standards help prevent the destruction of microchips, ICs, and other components that can be damaged by low-voltage discharges.

Secure Product Reliability

Adherence to the ESD guidelines minimizes the failures of PCB in early life and improves the overall performance.

Reduce Manufacturing wastage

The practices that are ESD-safe reduce the possibility of rejects in the production line, saving time and material costs.

Assist Quality Assurance and Testing

Standards help ensure uniformity of ESD protection throughout the inspection, handling, and testing processes.

Global Industry Standards compliant

Exporting and OEM partnerships usually require having certifications such as ANSI/ESD S20.20 and IEC 61340-5-1.

Increase the Brand Reputation and Customer Trust

The provision of high-quality products that are ESD safe over time develops a reputation in competitive electronic markets.

OVERVIEW OF KEY ESD STANDARDS AND COMPLIANCE GUIDELINES

To fully protect sensitive components during the PCB manufacturing and handling process, various internationally recognized ESD standards and guidelines have been established. The standards provide guidelines for the development, maintenance, and auditing of ESD control systems in manufacturing environments. Learning and practising these regulations not only secures your products but also assists in satisfying international compliance and enhances the credibility of your facility.

USA Standard ANSI/ESD S20.20 - ESD Control Systems

The ANSI/ESD S20.20 is one of the most widely used standards of ESD control. It provides a detailed prescription for designing and implementing a maintenance program within an ESD control program that protects electrical or electronic components. Partnership with many OEMs and foreign manufacturers necessitates certification against this standard.

IEC 61340-5-1 International Standard of ESD Protection

The standard, formulated by the International Electrotechnical Commission (IEC), describes general requirements for ESD-safe workplaces and personnel. It is concerned with the management of electrostatic discharge in electronic handling environments, making it a must-have in manufacturing industries that deal with international markets.

JEDEC JESD625- ESD-Sensitive Device Handling

This standard provides specifications for the safe handling, shipping, and storage of electronic devices susceptible to damage by ESD. Component suppliers and OEMs frequently use it to preserve component integrity during logistics.

MIL-STD-1686 U.S. Military ESD Standard (Legacy)

This military standard has been largely superseded by ANSI/ESD S20.20, but was historically a standard for ESD control in the defense-related electronics manufacturing industry. It remains a point of reference in the aerospace and military industries.

ISO 9001 and ESD Integration

Although ISO 9001 focuses on quality management systems, most electronics manufacturers incorporate ESD controls into their ISO processes to enhance compliance and traceability. This enhances audit preparedness and competitiveness globally.

EIA-625 - Requirements of Handling Electrostatic Discharge Sensitive Devices

This Electronics Industries Alliance (EIA) standard addresses personnel and packaging materials used in grounding ESD-sensitive devices. It is helpful for facilities that frequently handle manual assembly or PCBs.

BEST PRACTICES FOR IMPLEMENTING ESD CONTROL IN ASSEMBLY LINES

To prevent electrostatic damage during the manufacturing and handling of printed circuit boards (PCBs), it is essential to create an ESD-safe environment. A good Electrostatic Discharge (ESD) control program will not only protect components but also maintain product reliability, minimize failures, and ensure the product complies with industry standards. The following are the most practical ESD protection techniques that any electronics manufacturer needs to adopt to ensure a safe and compliant working environment.

Personnel Grounding and Grounding Systems

Ensure that all staff, equipment, and tools are properly grounded. Wear wrist straps, heel straps, and ESD-safe footwear that are grounded to the floor or the workstations. This is the initial barrier to static build-up.

ESD-Protected Workstations

Provide all assembly points with ESD-safe items, such as anti-static mats, grounded workbenches, and ionizers, to ensure a safe and controlled environment. Maintain the conductive surfaces clean, and ensure all tools are ESD-rated to prevent accidental discharges.

ESD Personal Protection Equipment (PPE)

Supply employees with conductive or dissipative lab coats, gloves, and smocks. This reduces the buildup of charges on the body or clothing during the assembly process.

Tools and Equipment ES-Safe

Only use certified ESD-safe tools, such as tweezers and soldering irons, and packaging materials that are designed to prevent charge buildup and release during handling and assembly.

Environmental Controls (Humidity and Flooring)

Maintain the humidity at optimal levels (typically 40-60%) to minimize the buildup of static charges. Place ESD-safe flooring or floor mats to ensure a continuous discharge path and reduce hazards associated with walking or movement.

Training and Certification Courses

Carry out ESD awareness training regularly for all employees. Ensure that personnel are aware of the formation of static electricity and the measures to prevent ESD incidents through proper procedures and safe handling of goods.

Regular ESD Auditing and Maintenance

Conduct regular audits on ESD to ensure compliance using field meters, testers, and logs. Conduct regular checks on old and discarded PPE and test the wrist strap and equipment's grounding connections often.

Labels and Signage

Place ESD warning labels and floor signs in areas that are sensitive to electrostatic discharge (ESD). This maintains ESD awareness and warns visitors and employees to exercise the necessary precautions.

Adopting these best practices not only reinforces your ESD control program but also improves production quality, minimizes expensive rework, and ensures that your work complies with international ESD guidelines, such as ANSI/ESD S20.20 and IEC 61340-5-1.

ESSENTIAL ESD-SAFE TOOLS AND EQUIPMENT FOR PCB HANDLING

Manual handling of printed circuit boards (PCBs) may cause latent or devastating damage unless it is performed with adequate ESD protection. It is essential to use ESD-safe tools and equipment to prevent damage to sensitive components during the manufacturing, testing, and packaging of the product. The following is a comprehensive list of anti-static tools and materials that should be present in every ESD-safe environment to ensure compliance and product safety.

ESD Wrist Straps

The most popular personal grounding equipment is the wrist straps. When attached to a ground point, they will safely dissipate any built-up static on the body, safeguarding components when they are being handled directly.

Anti-Static Mats and Work Surfaces, Tabletop

The ESD mats are dissipative, allowing for the safe neutralization of tool and component charges. Such mats usually are grounded to drive electrostatic charges out of sensitive equipment.

Conductive Footwear and ESD Heel Straps

Standing or walking on ESD-safe floors is ensured by being continuously grounded through the use of heel straps or ESD shoes. They are required to work away from grounded benches personnel.

Air Ionization Equipment (ionizers)

Ionizers release positive and negative ions to neutralise static electricity in a location where the ground could not be used, e.g. in cleanrooms or when working with non-conductive materials e.g. plastic.

Tweezers, Screwdrivers, etc. (ESD-Safe Tools)

Instruments of dissipative or conductive material inhibit the formation of static charges when performing delicate tasks. ESD-rated hand tools must always be used to prevent accidental damage to components.

ESD-Safe Trays and Bins

Store PCBs or ICs in conductive bins, trays, or component holders. These storage units help maintain a continuous discharge pathway and prevent static build-up.

ESD Grounding Plugs and Snap Connectors

Such accessories guarantee the grounding of all mats, straps, and tools. They provide safe connections to grounding points and require regular inspection and maintenance.

Testers and ESD Workstation Monitors

Real-time monitors verify that wrist straps, mats, and grounding systems are functioning properly. These instruments are critical to upholding an audit-ready ESD control program.

Protective Clothing and ESD Lab Coats

Static-dissipative clothing prevents the accumulation of charges on the body and the potential transfer of static electricity to delicate electronics.

The adoption of these tools in your ESD protection plan will ensure safe work with PCBs, enhance product quality, and conform to various international standards, including ANSI/ESD S20.20 and IEC 61340-5-1. Each of these equipment is important in establishing a solid ESD-safe working environment.

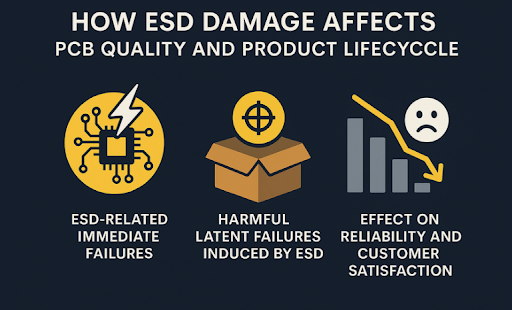

HOW ESD DAMAGE AFFECTS PCB QUALITY AND PRODUCT LIFECYCLE

Electrostatic Discharge (ESD) is a hidden hazard during PCB manufacturing that can lead to short-term and long-term damage to electronic components. Even a tiny discharge, imperceptible to the human eye, can permanently alter the performance of a microchip or even destroy it. Learning how ESD affects the quality and lifecycle of PCBs is the key to ensuring product reliability and preserving your brand image.

ESD-related Immediate Failures

Instant failures occur because static electricity causes the immediate destruction of a sensitive part. These errors are typically detected during in-house inspection or testing, resulting in increased rework, production delays, and higher manufacturing expenses.

Harmful Latent Failures Induced by ESD

The latent damage occurs when parts are not destroyed but rather weakened by ESD, which causes them to fail after product shipment. These invisible breakdowns lead to all kinds of expensive warranty returns, unsatisfied customers, and lower trust in your brand.

Effect on product reliability and customer satisfaction.

Undetected or repeated ESD events worsen the performance of the product, reduce its lifespan, and escalate field failure rates. This compromises overall customer satisfaction, and support costs are higher, potentially resulting in a loss of market competitiveness due to low reliability scores.

Manufacturers can mitigate these risks by making adequate investments in ESD control and compliance, extending the life cycle of their products, and producing high-quality electronics that meet industry standards.

COMMON MISTAKES TO AVOID IN ESD MANAGEMENT

Even an excellently planned ESD control program may fail due to poor maintenance. Most PCB companies inadvertently commit minor but potentially fatal errors in handling sensitive parts, leading to electrostatic damage. It is essential to identify and prevent such ESD management errors to ensure product integrity, minimize failures, and comply with industry standards and regulations.

1. Poor or Incorrect Grounding

One of the most common reasons for ESD incidents is the failure to properly ground personnel, equipment, or workstations. All ground connections must be safe, and they should be tested frequently. Additionally, the connections should be well-connected at a common grounding point.

2. Neglecting the Routine ESD Audits and Inspections

Failure to conduct regular audits results in failure of ESD systems that are not detected. Regular inspection of wrist straps, ionizers, and resistance values helps detect faults before they can lead to damage.

3. Worn-Out/Damaged ESD Gear

Excessive use of wrist straps, mats with degraded conductivity, or faulty heel straps may render them ineffective. ESD protection should be maintained by regularly checking and replacing old equipment.

4. Employee Training and Awareness Shortages

The staff may unintentionally fail to adhere to safety measures due to a lack of continuous ESD training. The constant learning will make employees aware of the risks associated with not moving, and they will consider the best handling practices.

5. Handling of ESD-Sensitive Devices

Grounding is required when touching circuit boards and should not be put on unprotected surfaces or stored in non-ESD containers, as this could introduce latent defects. The handling and packaging should always be anti-static.

6. Ignoring Environmental Factors

Static buildup is more prone to occur in low-humidity surroundings. Failure to observe or manage humidity levels will render even the best ESD arrangements ineffective.

These are the most common pitfalls to avoid when setting up a proper ESD control system, which minimizes the number of products that need to be sent back to the manufacturer due to ESD damage and ensures an ESD-free, safe PCB in the long term.

BENEFITS OF ADHERING TO ESD STANDARDS FOR MANUFACTURERS AND CLIENTS

Better Product Performance

Minimizes failures associated with static effects, enabling PCBs to perform well throughout the assembly and end application.

Lower Costs of Rework and Scrap

Reduces ESD-induced defects, thereby reducing material waste and downtime in production.

Adherence to International Laws

Complies with international standards for ESD, such as ANSI/ESD S20.20 and IEC 61340-5-1, and can therefore enter the global market.

Improved Brand Image

Provides high-quality products that foster customer loyalty and confidence.

Greater Customer Satisfaction

Quality products have a longer lifespan, lower returns, and fewer warranty claims.

Key Takeaways

Adopting and practicing strict ESD precautions is a worthwhile investment for any PCB manufacturer that prioritizes quality and reliability. In managing the risk of electrostatic discharge, companies can prevent damage to sensitive components, expensive failures, and even enhance the performance of a product throughout its life. The benefits of ESD compliance extend beyond ensuring smooth manufacturing processes; it also enhances the brand's reputation and increases customer satisfaction. Finally, the adoption of ESD standards is critical to the sustainable performance of the modern high-tech and precision electronics industry.

Ensure your PCBs are built to last with Tapren's ESD-safe manufacturing. Our advanced processes protect sensitive components from electrostatic damage, reducing failures and improving product reliability. Work with a trusted partner that prioritizes quality and long-term performance. Contact us today to get started.

FAQs

Is there a difference in ESD on multilayer PCBs compared to single-layer boards?

Yes, multilayer PCBs have components that are more densely packed and more sensitive, and hence can be more prone to hidden or latent ESD damage. Advanced multilayer designs should employ a higher level of care and stricter ESD controls.

Do you require ESD-safe gloves when wearing wrist straps?

Yes, wrist straps do not always completely prevent ESD when working with ultra-sensitivities. ESD-safe gloves offer additional protection by excluding direct contact with the skin and minimizing the charge accumulated in the hands.

Does mishandling of ESD have any impact on the solder joints or connections of the PCB?

Absolutely. ESD may weaken solder connections or cause microcracks, which can lead to intermittent faults, poor connectivity, or complete failure after prolonged use.

Next Read:

Things needed for Product launch on Crowdsourcing

Comments