Differences between LGA, PGA, and BGA

- TapRen Team

- 2 days ago

- 5 min read

Abstract

Chip packaging and socket interfaces play significant roles in electronics. They determine how processors, such as CPUs and microcontrollers, connect to circuit boards. Land Grid Array (LGA), Pin Grid Array (PGA), and Ball Grid Array (BGA) are three standard packaging types commonly used in modern circuits. These three have different designs, advantages, and disadvantages of their own. Additionally, these types of packaging forms significantly impact device size, performance, upgradeability, and repairability, making them vital considerations for users ranging from high-end desktops and servers to laptops, smartphones, and embedded systems. Going with the right packaging technology is crucial for DIY builders and manufacturers.

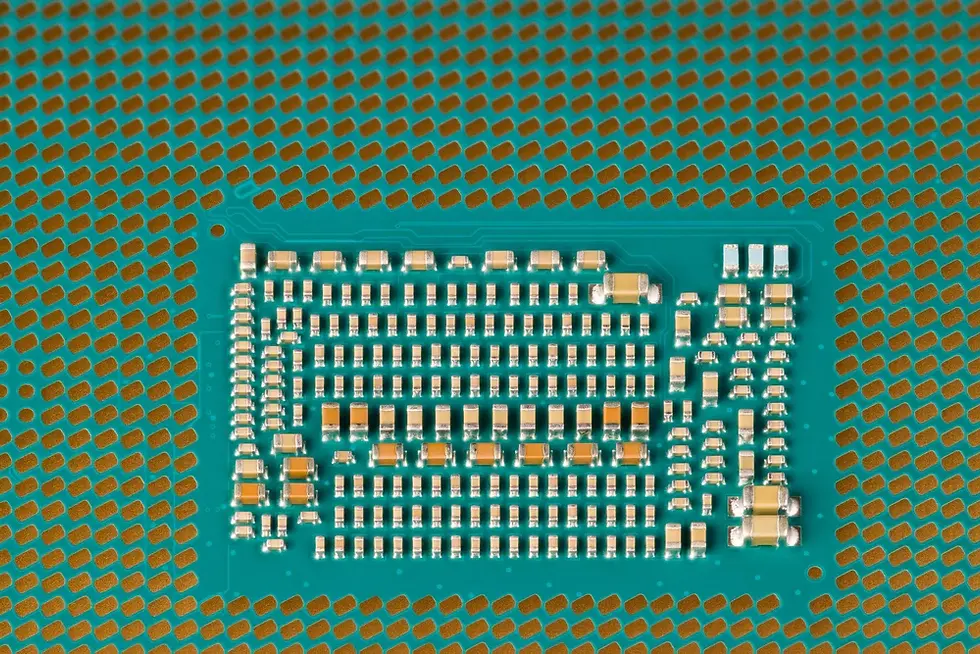

Land Grid Array (LGA)

Flat contact pads are created at the bottom of the chip, which are arranged in a grid layout. These contact points are flat metal pads and a socket on the motherboard that is compatible with this, which has springs or pins that touch these flat pads when the processor is positioned and engaged.

Key Features

Flat contact pads in a grid fashion.

Pins are directly placed into the sockets.

Generally, it is kept by a pressure plate and lever mechanism.

Support high pin density.

Advantages

Less likely to damage pins on the CPU when installing or handling.

Flat contacts are simpler to inspect and rework.

Consistent mechanical contact and better thermal control for high-end CPUs.

CPUs are simple to remove and can be replaced frequently for frequent upgrading.

Disadvantages

Pins on motherboard sockets remain flexible and should be treated with care while mounting.

Alignment of the mounting is necessary; misalignment will damage the socket.

Mildly pricier packaging than PGA.

Pin Grid Array (PGA)

It is the packaging where pins extend from the bottom of the chip package. Pins are inserted into the holes or sockets and are arranged in a grid pattern within the circuits.

Key Features

Solder balls instead of pins or pads

Permanently soldered to the circuit board

No socket required

Extremely compact design

Advantages

Easy to install and replace; ideal for DIY and repair purposes.

Straightening of pins is possible when they are bent, thus making them more tolerant.

Lower socket cost versus LGA.

Disadvantages

CPU pins are fragile and are more susceptible to bending and breaking.

Lower pin density, limiting application on high-performance CPUs.

Bigger package size versus LGA and BGA.

Ball Grid Array (BGA)

Ball Grid Array (BGA) is a packaging technology that is arranged in a layout on the bottom of the chip. The chip is placed on top of the circuit board, and then the entire package is heated so the solder balls can melt and become permanent connections.

Key Features

Solder balls instead of pins or pads

Permanently soldered on the circuit board

Socketing not necessary

Extremely compact layout

Advantages

Allows for the smallest chip size and the densest connections.

Improved heat dissipation and signal integrity.

Needed for miniaturized, high-performance electronics like smartphones and tablets.

Disadvantages

Non-user-replaceable; chips are soldered directly to the board.

Repair or replacement requires special equipment and expertise.

If solder balls are mislocated during manufacturing, the chip can be unusable.

Applications

A few applications for each packaging type are given below;

LGA

Used in high-end desktops, servers, and new Intel and AMD (AM5) CPUs.

PGA

Used in older AMD CPUs and some desktop and laptop processors.

BGA

Used on laptops, smartphones, embedded systems, and small electronics.

Comparison Table (LGA vs. PGA vs. BGA)

A comparison between different packaging types is outlined below;

Which One is Better?

The best type of chip packaging depends on several parameters, including the primary function, device size, budget, repair needs, and performance requirements. DIY builders prefer LGA or PGA for ease of flexibility. In contrast, makers choose BGA for small devices in large series where cost and space are the primary considerations for determining packaging forms.

DIY and Upgradability

LGA and PGA are better suited for PC building and upgrading devices. Changing CPUs is simple and does not require special tools, due to their design.

Device size and Portability

BGA takes the lead in small and portable devices, such as smartphones, tablets, and embedded systems. It is smaller and has a solid connection that can resist movement.

Performance Needs

High-end applications, such as game rigs or servers, can utilize LGA with its high pin count capability and firm power delivery. PGA is also beneficial, but not very suitable for high-end applications.

Manufacturing and Cost

BGA is cheaper on a large production basis and saves assembly time. However, LGA and PGA are more customer-friendly and versatile for small production or custom-made orders.

Repair and Maintenance

LGA and PGA are operator accessible. However, in BGA, it is difficult to remove or service with anything other than professional rework equipment, making it best suited for repair-oriented installations.

Adaptability and Backward Compatibility

LGA is becoming the standard for future CPUs, mainly from Intel and AMD. PGA is being phased out gradually, while BGA is gaining popularity in smaller and mobile markets.

Key Takeaways

LGA, PGA, and BGA are all essential chip packaging configurations, each optimized to suit different needs. LGA and PGA offer upgradability and easier repairs; therefore, they are employed where desktops and self-made constructions experience high demand. BGA allows for the most powerful, smallest devices, but loses user serviceability in the process.

As electronics become smaller and power demands rise, more BGA devices become prevalent, but LGA remains standard for modern and advanced systems. Customers' choices would depend on their preferences, as well as parameters such as upgradability, repairability, portability, and performance.

Selecting the right chip packaging is crucial for achieving optimal performance, durability, and design success. At TapRen, we support manufacturers and developers with expert PCB design for LGA, PGA, and BGA layouts tailored for everything from DIY upgrades to compact embedded systems. Need help with your board layout or socket compatibility? Contact us or request a quote to get started today.

FAQs

Why does Intel use LGA?

Intel uses LGA (Land Grid Array) in processors because it uses more pins, which enhances performance and data transfer speed. LGA offers more stability and longevity than other packaging techniques, making it an essential choice for running high-performance systems, such as gaming PCs and servers.

How to fix bent LGA socket pins?

Warped LGA socket pins require careful and patient straightening. Then bend them back using a small tool, such as a precision screwdriver or needle. Additionally, it can be resolved by using a dedicated pin-straightening tool for LGA sockets. It should be handled with care to avoid breaking or damaging the pins.

How are LGA, PGA, and BGA chip packages related to issues of current technology?

Modern-day devices need more power, efficiency, and miniaturization. LGA and BGA packages enable high-performance CPUs for AI, cloud computing, and data centers, while ultra-dense design is enabled by BGA for smartphones and IoT applications, delivering smaller, faster, and more efficient electronics

How do global supply chain problems affect chip packaging capabilities?

Supply chain disruptions can impact the availability of specific chip packages. High-volume manufacturing favors BGA, while LGA and PGA are more common in repair- and upgradability-oriented markets, which influence manufacturer decisions in times of uncertainty.

Next Read:

8 Requirements for Military-Grade PCBA

Comments