Manual Soldering Tips and SMT Soldering

- TapRen Team

- Jan 14

- 7 min read

Updated: 2 days ago

Abstract

A poorly soldered joint can ruin an entire electronic device. This is also a problem that even the most experienced professionals encounter. Properly joining the components within the board helps make the electronics compact and quicker. Soldering has greatly evolved from ancient goldsmiths using heat to current factories employing automated SMT lines. Being familiar with manual and SMT soldering is necessary today to assemble and repair trustworthy circuits. This article explains the fundamentals, step-by-step processes, and tricks for mastering both methods, as well as when to use each one effectively.

What is Manual Soldering?

Manual soldering involves physically mounting electronic components onto a printed circuit board using a soldering iron and a low-melting-point metal alloy. It is a necessary process for prototyping, repair, and trial runs where fineness and versatility meet.

Key Applications and Tools Used in Soldering

Major applications of Manual soldering are:

It is for fixing or modifying components in electronic circuits.

Manual Soldering can also be used to test new circuit designs quickly.

Soldering is needed to join components that are difficult to connect using machines.

It is suitable for learning to design new circuits as a hobby, too.

Some of the tools for soldering are as follows:

Soldering iron (the adjustable temperature model is best)

Lead-free solder

Soldering iron stand

Soldering Wick

Tweezers, cutters, and pliers

Flux (to improve solder flow)

Ventilation fan or fume extractor

A magnifier or microscope for inspection

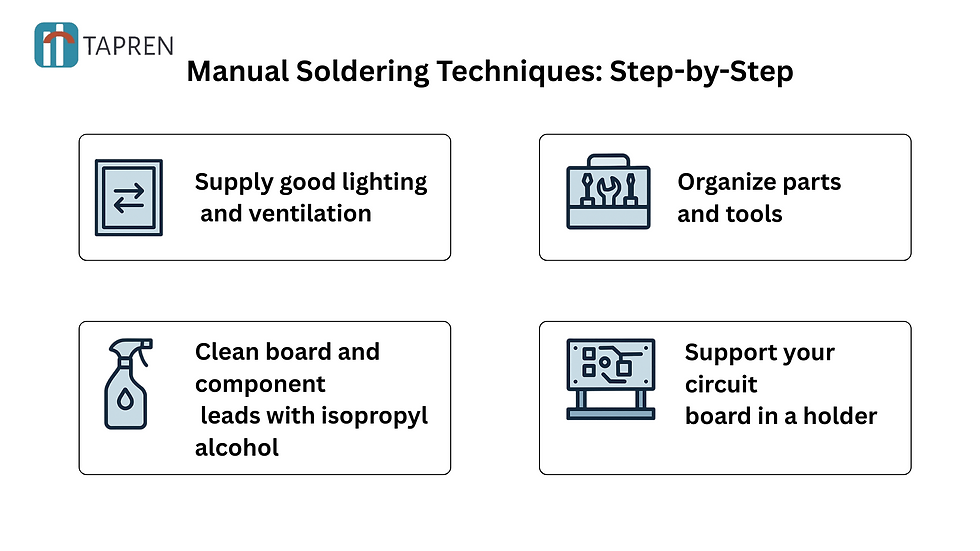

Manual Soldering Techniques: Step-by-Step

Here, the steps for manual soldering are given.

Preparing Your Workspace

Supply good lighting and ventilation

Organize parts and tools

Clean the board and component leads with isopropyl alcohol

Support your circuit board in a holder

The Four-Step Method for Perfect Joints

Heating the Joint

In this part, one should fix the components as well as the pad beside the tip of the iron..

Applying Solder

Place the solder against the heated joint.

Cooling and Inspection

Drop solder first, then iron. Allow the joint to cool naturally.

Finishing

Trim off surplus component leads and verify your work.

Common Mistakes to Avoid

Inadequate heating of joints results in poor, grainy joints that ultimately fail.

Creating unsolicited solder bridges between neighboring connections can cause short circuits.

Soldering more than necessary can consume more material and hide poor contacts underneath.

Overheating can damage delicate components and cause copper traces to peel away from the board.

Failing to remove flux residue can lead to corrosion and contact issues later.

What is SMT soldering?

SMT soldering is a method of attaching small electronic components to the surface of a PCB, rather than inserting leads through holes. SMT helps pack the components efficiently on the surface, making the PCB board faster and more efficient.

Why is SMT taking over electronics?

Surface-mount technology is revolutionizing the electronics world by miniaturizing devices and making them lighter. SMT places components evenly on both sides of the board, which enhances performance and signaling. SMT is a manufacturer's favorite because it enables automated assembly lines to operate more efficiently and rapidly. Today's incredibly compact yet powerful devices are pocket-sized and do more than ever due to this technology.

Step-by-Step SMT Soldering

A few steps are as follows;

Hand-Placing Components

Use tweezers to carefully place small components, such as resistors or chips, on the solder-pasted pads. Ensure each part is correctly aligned before proceeding to the next step.

Reflow Techniques (Hot Air vs. Oven)

After all the parts are fixed onto the board, soldering can be done using hot air or in an oven, depending on the size of the components.

Fixing Tombstoning and Solder Bridges

Tombstoning occurs when a component part improperly lifts upward. To fix this, apply flux and use a soldering iron or wick to correct the problem.

Hybrid Techniques: When Manual Process Meets SMT

This technique combines manual and SMT methods for adding components to the board through holes and surface mounting. For example, attaching a large connector requires a soldering iron, whereas adding small, irregularly shaped parts can be done by hand. Additionally, reflow ovens and tweezers are used to place tiny surface-mount technology (SMT) components onto the board. This manual addition places the components effectively and ensures a secure attachment, making it suitable for designing prototypes or running smaller projects that cannot be achieved using machines.

Advanced Tips for Manual and SMT Soldering

A blend of different methods in modern technology can enhance the product process and performance for the betterment.

Hand-Placing Parts

Add small components, such as chips, using tweezers on the pads that have been solder-pasted. Make sure that the components on the board are placed in the correct alignment.

Solving Tombstoning and Solder Bridges

If the component extends upwards after surface mounting, it is referred to as tombstoning. This needs to be repaired through solder bridging, which can be achieved by using an iron soldering tool or applying flux.

Reflow Method

Soldering is typically performed using two reflow methods, which involve heating to ensure the components are securely attached to the board. This may be done using hot air or a reflow oven.

Solder Selection

For general purposes, Tin-lead solder is feasible as it melts at lower temperatures and also flows well. Likewise, Lead-free solder can also be used, but it requires a higher temperature for melting and is environmentally friendly.

Flux Types

Multiple flux types can be utilized based on the application. No-clean flux is a time-saving option as it can be used directly after soldering without cleaning. Meanwhile, water-soluble flux is a much cleaner option, but it must be washed off thoroughly. Furthermore, Rosin flux allows a smooth flow of solder in the joints.

Safety Precautions

Safety is the main priority during soldering. Ensure the working area is well-ventilated to allow passage for any hazardous fumes. Always wear personal protective gear, such as eyeglasses, gloves, and closed-toe shoes, and cover your entire body to ensure the safety of personnel and enhance the quality of the device.

Comparing Manual and SMT Soldering

A general difference in comparing manual and SMT soldering highlights are as follows;

Aspect | Manual/Through-Hole | SMT |

Component size | Larger | Much smaller( down to 01005) |

Tools required | Basic, affordable | More specialized, costlier |

Beginner-friendly | Yes | Steeper learning curve |

Repair ease | Easier | More challenging |

Space efficiency | Less efficient | Very space-efficient |

Production suitability | Small runs, prototypes | Mass production |

Quality Control and Inspection

Some of the few ideas for checking the quality of the products are as follows:

Visual Inspection Tips

Inspect each joint thoroughly to ensure a shiny finish and shape. Ensure all components sit flat and straight, and inspect closely for any solder bridges or cold joints.

Using Multimeters and Microscopes

To test the connection between two points, use a multimeter’s continuity mode. For small parts, a magnifying glass or microscope helps you spot tiny defects and poorly formed solder joints.

Introduction to IPC Standards

IPC-A-610 outlines the quality standards for soldered connections. Beginners should learn to identify good versus bad joints, check for proper solder coverage, and follow correct lead-trimming practices.

Case studies

Thermal influences on IC packages during the manual soldering process

This study investigated the impact of manual soldering on the temperature of small electronic components. Using simulations and real experiments, researchers tested three types of surface-mount devices (SM0402, SOT23-3, MSOP10). The experiment revealed that smaller components tend to heat faster than larger ones. Additionally, the flow of solder material and its solder iron angle(90° vs. 30°) also impacted temperatures. 30° angle and controlled soldering helped avoid damaging components, making manual soldering safer and more predictable.

Source: A. Fodor, R. Jánó and D. Pitică, "Thermal influences on IC packages during manual soldering process," Proceedings of the 2014 37th International Spring Seminar on Electronics Technology, Dresden, Germany, 2014, pp. 54-57, doi: 10.1109/ISSE.2014.6887562.

Research on SMT solder joint image segmentation

Researchers from Hengyang Normal University and Guilin University developed a method to improve image segmentation of SMT (Surface Mount Technology) solder joints. They converted RGB images to HSV format, applied 2D histogram thresholding in color space, and used mathematical morphology to enhance accuracy. This method helps identify solder joint defects more clearly, aiding quality control in electronics manufacturing. Their approach enhances reliability and possesses genuine engineering value.

Source: Yaqi, Sun, & Yu, Liu. (2012). Research on SMT solder joint image segmentation. 1287-1289. 10.1109/ICEPT-HDP.2012.6474841.

Key Takeaways

In electronics, both Manual soldering and SMT soldering have equal significance. Manual soldering is preferred for adding unique components and performing small repairs and runs. SMT is generally used in modern electronics that require high speed and miniaturization. Both of these techniques can be applied to various applications, and understanding each one helps in assembling and designing circuit boards and advanced electronics.

Want precision soldering that brings your boards to life? At TapRen, we combine expert manual soldering and advanced SMT techniques to ensure flawless assembly, whether you're prototyping, repairing, or scaling for mass production. From tiny SMT components to through-hole repairs, we’ve got you covered. Contact us or request a quote to get started today.

FAQs

1. What are the serious environmental concerns related to soldering?

Hazardous chemical fumes and toxic metals might be released into the environment while soldering. If these poisonous compounds mix in the air and water, they cause adverse effects on the ecosystem. Lead-free solder and effective ventilation can help minimize these dangerous effects.

2. What is the preferred temperature for iron soldering?

Generally, a temperature range of 350°C to 400°C is preferred for a soldering iron. This temperature is sufficient to melt the iron for soldering and prevent damage to components. Temperature beyond this range may not allow soldering or cause damage to the circuit board.

3. Why is SMT soldering preferred in modern electronics?

SMT provides a method for designing miniature and powerful electronics. Tiny components are fitted and joined in the circuit board, which helps to save space making it faster and cheaper. SMT soldering also enables the design of electronics that can be used for automation.

4. How can the solder paste and soldering materials be selected for SMT soldering processes?

An essential step in the soldering process is selecting the right paste, which must also be compatible with the PCB units. Likewise, proper solder flow ensures reliability during the soldering process.

Comments